Many engineers face the tough choice between 6063-T5 and 6061-T6 aluminum alloys. Both have unique strengths, but which one actually delivers better value for your project? Let's break it down.

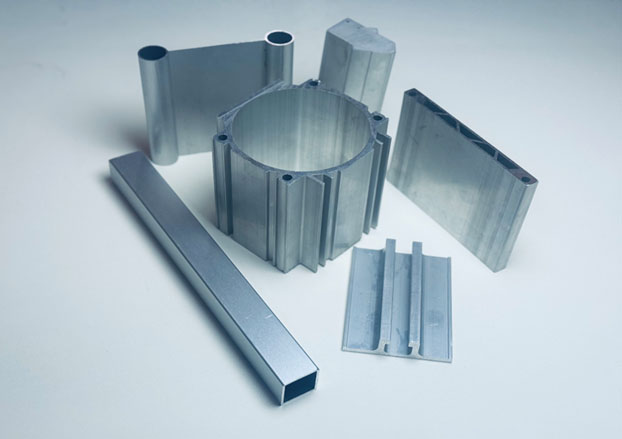

6063-T5 offers better formability and surface finish at lower cost, while 6061-T6 provides higher strength and durability. 6063 is ideal for extruded shapes like heat sinks, while 6061 excels in structural applications requiring more strength.

The aluminum alloy selection process comes down to three key factors: application requirements, budget constraints, and manufacturing process.

The right alloy saves money and prevents failures. Here's what separates these two popular options.

6063-T5 contains less alloying elements (0.2-0.6% Si, 0.45-0.9% Mg) making it softer and more formable. 6061-T6 has more additives (0.8-1.2% Mg, 0.4-0.8% Si, 0.15-0.4% Cu) giving it higher strength but less workability.

Key mechanical property differences:

| Property | 6063-T5 | 6061-T6 |

|---|---|---|

| Tensile Strength | 27 ksi | 45 ksi |

| Yield Strength | 21 ksi | 40 ksi |

| Elongation | 12% | 8% |

| Hardness | 60 HB | 95 HB |

| Shear Strength | 17 ksi | 30 ksi |

The practical impacts:

6061 is 66% stronger in tension

6063 bends and forms much easier

6061 better resents dents and impacts

6063 extrudes more complex shapes

For simple brackets or cosmetic parts, 6063 often works well. When strength is critical, 6061 is the clear choice.

Material costs add up fast in production. Smart choices here significantly impact your bottom line.

6063 typically costs 10-20% less than 6061, mainly due to lower alloy content and easier processing. However, 6061's strength can sometimes allow using less material, offsetting the price difference.

Breakdown of cost factors:

Raw Material Costs

6063: $1.80-$2.20/lb

6061: $2.00-$2.50/lb

Fabrication Expenses

6063 requires 20% less extrusion force

6061 needs more robust tooling

Machining time typically shorter with 6061

Secondary Savings

6061's strength may allow thinner sections

Fewer supports needed in structural uses

Better anodizing can reduce finishing costs

Real-world example: A typical heat sink might need 15% more 6063 than 6061 by volume - but still costs less because the alloy itself is cheaper and extrudes more easily.

Each fabrication method favors different material properties. Matching process to alloy maximizes productivity.

For extrusion and bending, 6063 works better. For machining and welding, 6061 performs better. Consider how you'll make the part, not just how it will be used.

Manufacturing method comparisons:

| Process | 6063 Advantage | 6061 Advantage |

|---|---|---|

| Extrusion | Flows easier, complex shapes | - |

| Bending | Less springback, tighter radii | - |

| Machining | - | Better chip control |

| Welding | - | Stronger joints |

| Stamping | Easier forming | - |

| Anodizing | - | Higher quality finish |

Key recommendations:

Choose 6063 for complex extrusions

Use 6061 for machined components

Specify 6061 when welding is required

Consider 6063 for stamped or bent parts

6061 works better for high-end finishes

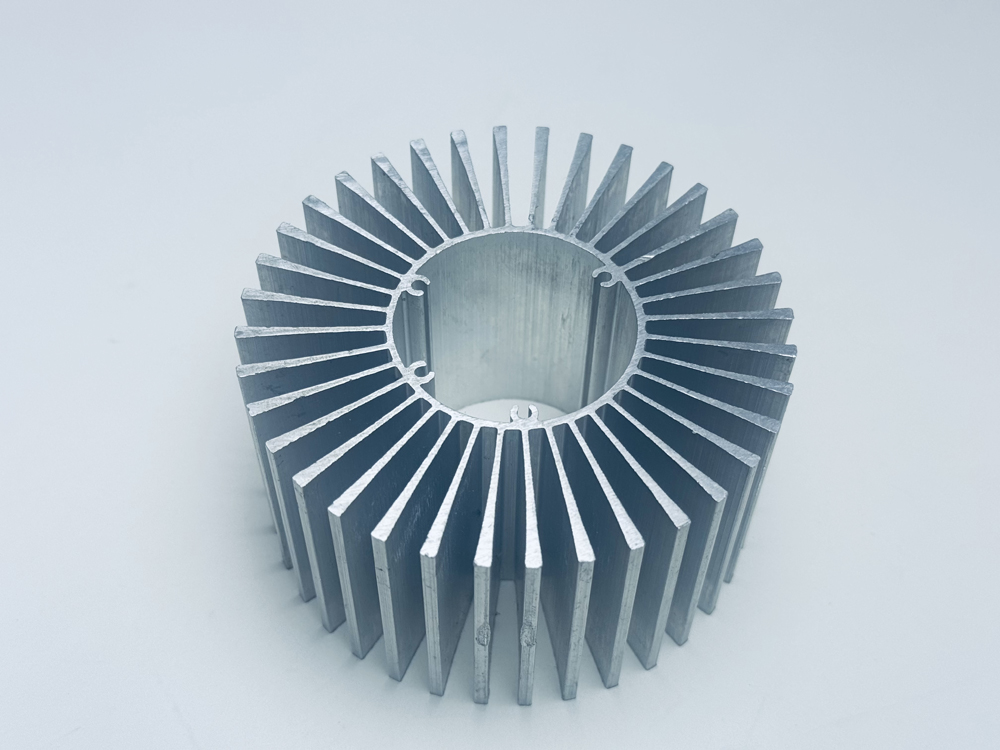

Heat sinks demand excellent thermal conductivity combined with easy manufacturing. Both alloys work, but one clearly outperforms.

6063-T5 is superior for heat sinks due to its better extrusion properties, thermal conductivity (201 W/m·K vs 167 W/m·K for 6061), and cost-effectiveness. Its smoother surface also improves heat dissipation.

Several technical factors make 6063 the preferred choice for thermal management applications:

Extrusion Performance

6063 extrudes more easily at lower pressures

Allows for more complex heat sink fin designs

Produces better surface finish out of the die

Thermal Characteristics

Higher thermal conductivity (201 vs 167 W/m·K)

Lower thermal resistance in finished parts

More consistent performance across temperature ranges

Cost Considerations

Lower raw material costs

Reduced tooling wear during extrusion

Less machining required post-production

Our experience shows 6063 maintains dimensional stability better during high-volume aluminum heat sink production. The alloy's composition (0.2-0.6% Si, 0.45-0.9% Mg) creates an optimal balance for thermal applications.

Surface treatment decisions significantly impact product longevity. The right alloy makes all the difference.

6061 accepts anodizing better than 6063, achieving more uniform and durable coatings. Its higher copper content (0.15-0.4%) creates stronger oxide layer adhesion during electrochemical processing.

The anodizing performance gap stems from fundamental material differences:

| Characteristic | 6061-T6 | 6063-T5 |

|---|---|---|

| Coating Uniformity | Excellent | Good |

| Layer Adhesion | 8-10/10 | 6-8/10 |

| Color Consistency | High | Medium |

| Corrosion Resistance | 15+ years | 10-12 years |

| Wear Resistance | 20% better | Baseline |

6061's superior anodizing comes from:

More uniform alloy composition

Higher impurity tolerance

Better response to Type II and Type III anodizing

For architectural components or marine hardware requiring premium finishes, we recommend 6061 despite its higher cost. The long-term performance justifies the investment.

High-temperature applications push aluminum to its limits. Not all alloys perform equally under thermal stress.

For continuous high-temperature service, 6061-T6 outperforms 6063-T5. It maintains strength up to 250°C (480°F) compared to 6063's 200°C (390°F) limit. Both alloys anneal above these temperatures.

The heat resistance hierarchy among common alloys:

2000 Series (Aircraft Alloys)

2024: Best for 150-175°C (300-350°F)

2219: Up to 250°C (480°F) intermittent

6000 Series (Structural Alloys)

6061: Best 6000 series for heat (250°C continuous)

6063: Adequate for 200°C service

7000 Series (High Strength)

7075: Avoid above 120°C (250°F)

Key considerations for high-temp applications:

Strength retention over time

Creep resistance at operating temps

Thermal expansion characteristics

Post-exposure mechanical properties

While specialty alloys exist for extreme conditions, 6061 remains the practical choice for most industrial applications needing balanced performance.

6063-T5 excels in heat sinks and extrusions, while 6061-T6 wins for structural strength and high-temperature use. The optimal choice depends on your specific requirements and budget.

Reference: