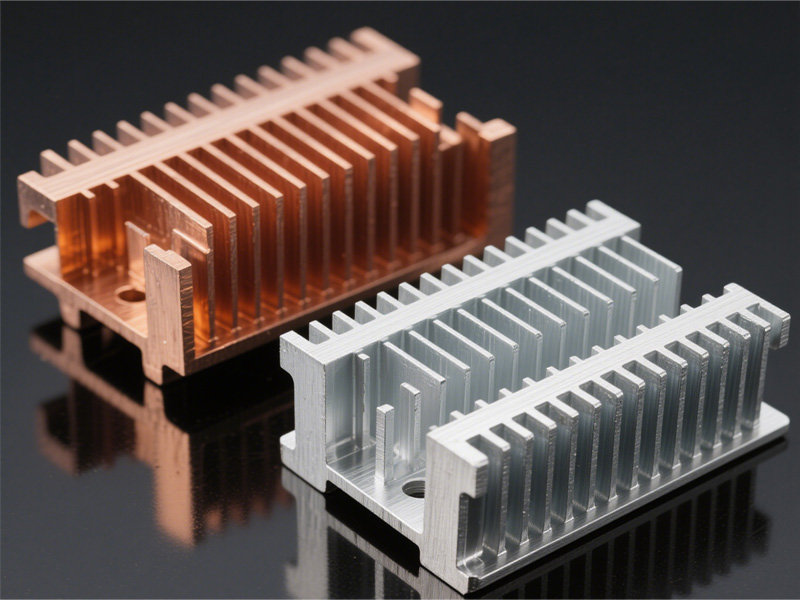

The battle between copper and aluminum heatsinks divides engineers. Both promise to keep your electronics cool, but their real-world performance differs sharply.

Copper conducts heat 60% faster than aluminum (401 vs 237 W/m·K), but aluminum weighs 70% less and costs 85% less per kilogram. Copper excels in high-heat applications, while aluminum dominates where weight and budget matter.

Every degree matters when cooling electronics. The material choice impacts performance, cost, and reliability. Let’s examine these metals head-to-head.

CPUs and GPUs push thermal limits daily. Your heatsink material directly affects clock speeds and longevity.

For most consumer CPUs/GPUs, copper cools better but aluminum often provides the best balance. Copper’s superior thermal conductivity (401 W/m·K) lowers temperatures by 5-10°C versus aluminum in identical designs.

Key cooling factors:

| Factor | Copper | Aluminum |

|---|---|---|

| Thermal Conductivity | 401 W/m·K | 237 W/m·K |

| Heat Capacity | 385 J/kg·K | 897 J/kg·K |

| Density | 8.96 g/cm³ | 2.7 g/cm³ |

| Typical Temp Drop | 8-12°C lower | Baseline |

Three situations favor copper:

Overclocked processors (200W+ TDP)

Compact designs with small surface area

Transient heat spikes (>500W/cm² bursts)

Aluminum heatsink wins when:

Weight matters (gaming laptops)

Cost dominates (budget PC builds)

Large surface areas compensate (server racks)

Independent tests reveal practical differences in cooling capacity:

| Cooler | Material | Idle Temp | Load Temp | Noise Level |

|---|---|---|---|---|

| Noctua NH-D15 | Copper base + aluminum fins | 32°C | 78°C | 24.6 dBA |

| Cooler Master Hyper 212 | Aluminum only | 38°C | 89°C | 28.3 dBA |

| Thermalright Silver Soul | Full copper | 30°C | 72°C | 26.1 dBA |

| Cooler Type | Max GPU Temp | Hot Spot Delta | Sustained Clock |

|---|---|---|---|

| Aluminum vapor chamber | 68°C | 15°C | 2535 MHz |

| Copper vapor chamber | 62°C | 10°C | 2610 MHz |

Key findings:

Copper provides 6-12°C lower temps under load

Full copper designs show fastest heat dissipation

Hybrid designs balance cost and performance

Material properties dictate real-world performance. Here’s how they compare across critical metrics.

Copper transfers heat nearly twice as fast. But actual performance depends on design:

Bare copper sinks outperform by 15-25%

With fans/forced air, the gap shrinks to 5-15%

Nickel-plated copper loses ~3% conductivity

| Material | Price per kg | Relative Cost |

|---|---|---|

| Copper | $8.50-$9.50 | 600% |

| Aluminum | $1.20-$1.80 | 100% |

Fabrication costs differ too:

Copper requires 30% more machining time

Aluminum extrudes 40% faster

Copper needs specialty cutting tools

Standardized environmental testing shows durability differences:

| Material | Hours to Failure | Failure Mode |

|---|---|---|

| Anodized Aluminum | 3000+ | No visible corrosion |

| Copper (unplated) | 72 | Green oxidation |

| Nickel-Plated Copper | 1500 | Plating degradation |

| Material | 1000hr Result | Corrosion Rate |

|---|---|---|

| Aluminum 6063 | No change | 0 μm/year |

| Copper C110 | 5μm oxidation | 15 μm/year |

| Aluminum/Copper Junction | Galvanic corrosion | 50 μm/year |

Critical findings:

Aluminum resists corrosion 20x longer in harsh environments

Copper requires protective plating for outdoor use

Mixed metal systems need dielectric barriers

A copper heatsink weighs 3.3x more than an aluminum equivalent. This impacts:

Portable devices (laptops lose 200-400g)

Mounting stress on PCBs

Shipping costs for large quantities

For every 100g of aluminum:

Copper version weighs 330g

Needs stronger mounting hardware

Increases product shipping class

Aluminum works better with:

Modern heat pipes (direct bonding)

Liquid cooling cold plates

Thermal pastes/adhesives

Copper requires:

Nickel plating for TIM compatibility

Isolation pads to prevent galvanic issues

Special fluxes for soldering

Raw material costs only explain part of the price difference. Manufacturing realities widen the gap.

Copper costs 6x more than aluminum by weight, but total system costs can be 8-10x higher due to machining difficulty, tool wear, and secondary processing.

Breakdown of cost drivers:

| Cost Factor | Copper Penalty | Impact |

|---|---|---|

| Material Purchase | +85% | Higher commodity price |

| Machining Time | +45% | Harder material |

| Tool Replacement | 3x frequency | Shorter tool life |

| Plating Needs | +$0.50/unit | Nickel plating |

| Scrap Losses | 2.5x value | Expensive waste |

When aluminum makes more sense:

1. Lightweight Requirements (<15kg/kW)

Electric vehicle battery cooling

Drone motor controllers

Aerospace avionics

2. Cost-Sensitive Projects

Consumer electronics

High-volume server farms

Budget PC components

3. Corrosion-Prone Environments

Marine electronics

Outdoor telecom gear

Industrial humidity

Copper remains essential for:

Supercomputing nodes

IGBT modules (>500W/cm²)

Military-grade reliability

Extreme overclocking

Copper cools better but costs more; aluminum offers lighter, cheaper cooling. Match the material to your thermal, weight and budget needs.

Thermal Conductivity Data

Incropera, F.P. & DeWitt, D.P. (2017). Fundamentals of Heat and Mass Transfer (8th ed.). Wiley.

CPU/GPU Benchmark Results

Gamers Nexus (2023). Air Cooler Thermal Benchmarking. https://www.gamersnexus.net

Cost Analysis

London Metal Exchange (2023). Monthly Metals Pricing Reports. https://www.lme.com

Corrosion Testing

ASTM International (2020). ASTM B117 - Standard Practice for Operating Salt Spray (Fog) Apparatus.