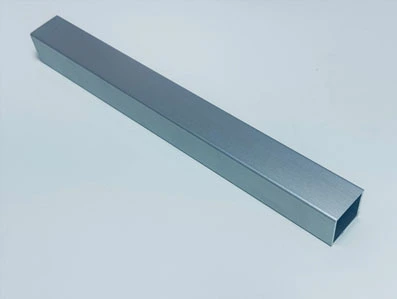

Aluminum tubes are tubular materials made primarily from aluminum and its alloys. These tubes are characterized by their low density, high strength, and corrosion resistance, along with excellent thermal and electrical conductivity. During use, aluminum tubes react with oxides to form a robust protective layer that prevents further oxidation.

Standard aluminum tubes boast a series of impressive advantages, making them highly effective materials in consumer goods, recreational products, automotive applications, and various manufacturing industries. When selecting the type of tubing, the variety of alloys and toughness in both aluminum and stainless steel can be overwhelming. However, unlike many other alternative materials, aluminum offers a broader range of benefits and can typically function under various pressures and stresses.

Among the many advantageous properties of aluminum, its low density and corrosion resistance through passivation make it an indispensable material in the aerospace, automotive, and construction industries. Aluminum is frequently used in designs such as window frames and other structural components. Its strength is also notably high, especially considering its weight is only 1% that of steel. Due to the combination of strength and flexibility, aluminum tubes have a larger volume per unit weight, making them particularly suitable for products with mobility functions, such as wheelchairs and outdoor furniture.

Aluminum also has excellent heat absorption properties, making it an ideal material for temperature control applications like refrigerators, solar panels, and air conditioning systems. Aluminum alloy 6061, known for its higher weldability and excellent corrosion resistance, is used by manufacturers in many medium to high-strength applications.

The versatility of aluminum allows it to play a significant role in many industries. Outdoor recreational product manufacturers can use aluminum tubes to make tent poles, camping chair frames, and outdoor tables. Aerospace, automotive, and railway transportation manufacturers use aluminum tubes in fuselages, hydraulic systems, and fuel lines. Due to its thermal conductivity, aluminum is the best alternative to steel or other heavy metals in refrigerators, engines, and HVAC systems. It can also be used to support chain-link fences, line tables, and house the casings of electrical equipment like desktop displays. The high surface smoothness of aluminum alloy 6063 makes it widely used by manufacturers. Since the strength of aluminum alloy 6063 is about half that of aluminum alloy 6061, aluminum alloy 6063 is often the right choice for applications where aesthetics are more important than strength.