Aluminum profiles refer to aluminum materials that are extruded into desired shapes under high pressure through molds, forming specific cross-sectional shapes and dimensional precision. Photovoltaic aluminum profiles are those used in the photovoltaic (PV) field. Due to their characteristics such as light weight, corrosion resistance, good thermal conductivity, high strength, ease of transportation and installation, and long service life, they are suitable for manufacturing supports and frames for PV modules.

From the perspective of the industry chain, the upstream involves the production of aluminum metal, mainly including bauxite, alumina, and electrolytic aluminum. The midstream involves processes such as extrusion, aging, and surface treatment to produce photovoltaic industrial aluminum profiles. The downstream involves the fine processing of aluminum profiles to make components such as photovoltaic frames and photovoltaic supports.

Based on production capacity, the CR5 (Concentration Ratio of the top 5 enterprises) of China’s photovoltaic frame industry reached 48% in 2022, with leading enterprises holding nearly half of the market share. This is mainly because most leading enterprises implemented various degrees of expansion plans after 2021. As the production capacity of leading enterprises continues to expand, the CR5 of China’s photovoltaic frame industry is expected to continue to rise.

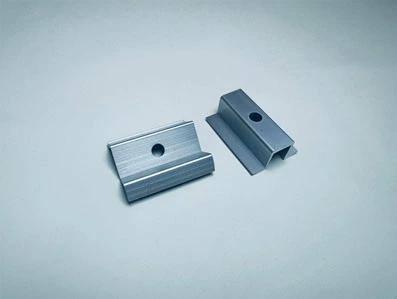

Photovoltaic aluminum profiles are processed into components such as photovoltaic fixed frames and photovoltaic supports, mainly serving to fix and seal solar cell modules, enhance module strength, and facilitate transportation and installation. The penetration rate in photovoltaic modules is about 90%, accounting for approximately 8-9% of the total cost of photovoltaic modules, making it difficult to replace. As the new energy photovoltaic industry continues to maintain a high level of growth, the production of photovoltaic aluminum profiles in China reached 2.6 million tons in 2022, a 30% increase from the previous year.

With the advancement of environmental protection concepts in the photovoltaic industry, favorable policies for the development of the photovoltaic industry are emerging one after another. The application of aluminum alloys in this field is becoming increasingly prominent. Photovoltaic supports have transitioned from steel products to aluminum profiles. In the current situation where the aluminum profile market is relatively stable, orders for photovoltaic aluminum profiles are booming, indicating a broad market prospect. Since aluminum profiles are mainly used in the photovoltaic industry in the form of frames and supports, photovoltaic aluminum profile enterprises need to stimulate product innovation capabilities to secure a place in the fierce market competition. Emphasis should be placed on the development of the service life and safety of photovoltaic aluminum profiles.