In industries such as construction, machinery, and electricity, tubes serve as crucial structural materials and are widely used in various applications. Aluminum tubes and iron pipes are two common types of piping materials, each with distinct differences. Below, we will delve into the differences between aluminum pipes and iron pipes, as well as their respective advantages and disadvantages.

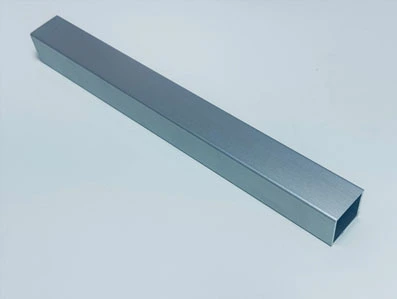

Aluminum pipes are tubular materials primarily made from aluminum and its alloys. They are characterized by low density, high strength, and excellent corrosion resistance. Additionally, aluminum pipes have good thermal and electrical conductivity. During use, aluminum pipes react with oxides to form a robust protective layer, preventing further oxidation.

Iron pipes are tubular materials primarily made from carbon steel or alloy steel. They have a higher density and greater toughness, and are relatively hard. Depending on specific needs, iron pipes can undergo heat treatment to enhance their strength and corrosion resistance.

Low Density and Lightweight: Aluminum pipes have a density of only 2.7 g/cm³, which is about three times lighter than steel (7.85 g/cm³). This makes them more suitable for applications such as ceilings and decorations.

Excellent Corrosion Resistance: Aluminum pipes automatically form an oxide film on their surface, which has excellent corrosion resistance and is not prone to rust. This makes them ideal for use in humid and corrosive environments.

Recyclability: Aluminum materials have high strength and a low melting point, allowing them to be recycled and reused. This reduces resource waste and costs, making them more environmentally friendly.

High Hardness and Durability: Iron pipes are harder than aluminum pipes, offering more stable and robust performance. They are suitable for use as critical support structures and load-bearing components.

High Temperature Resistance: Iron materials are more resistant to high temperatures and can be used in high-temperature environments. Ordinary carbon steel pipes can be used long-term at temperatures below 800°C, while alloy pipes can withstand even higher temperatures.

Due to their lightweight and corrosion-resistant properties, aluminum pipes are often used in construction, electricity, food, pharmaceuticals, and automotive manufacturing. For example, in the automotive industry, aluminum pipes are widely used in the manufacture of car radiators. In construction, aluminum pipes are used for various types of structures and decorations.

Iron pipes, known for their sturdiness and durability, are widely used in construction, transportation, petrochemicals, and machinery manufacturing. For instance, in the construction industry, iron pipes are used in building houses, bridges, and steel structures. In the petrochemical industry, iron pipes are used for oil pipelines and gas transmission pipelines.

In summary, aluminum pipes and iron pipes differ in material composition, advantages, and application scenarios. Aluminum pipes are lightweight and corrosion-resistant, making them suitable for lighter applications. In contrast, iron pipes are robust and durable, making them ideal for heavy-duty, large-scale construction structures or load-bearing components. Therefore, when selecting piping materials, it is essential to consider the usage environment, requirements, and various economic and social factors to choose the most suitable material.