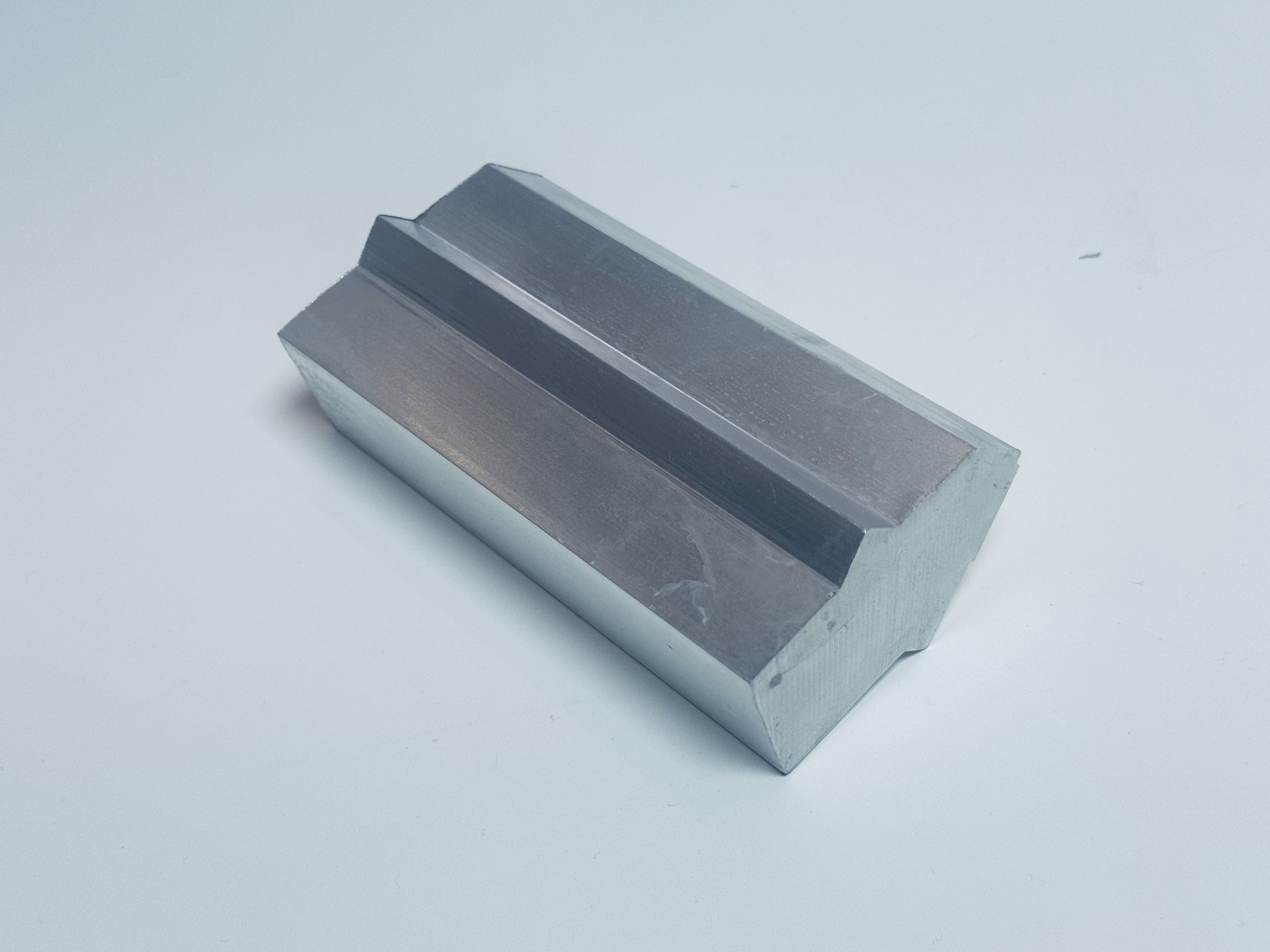

Custom Aluminum Extrusions for Every Application – Precision Engineered from 2020 to 8080 Alloys

Why Our Extrusions Stand Out

±0.1mm Tolerance – Perfect Fit for Complex Designs

Anodizing/Powder Coating Options for Durability

ISO 9001 Certified | 50,000+ Tons Annual Capacity

24-Hour CAD Support & Prototyping

Choose the Right Alloy for Your Project

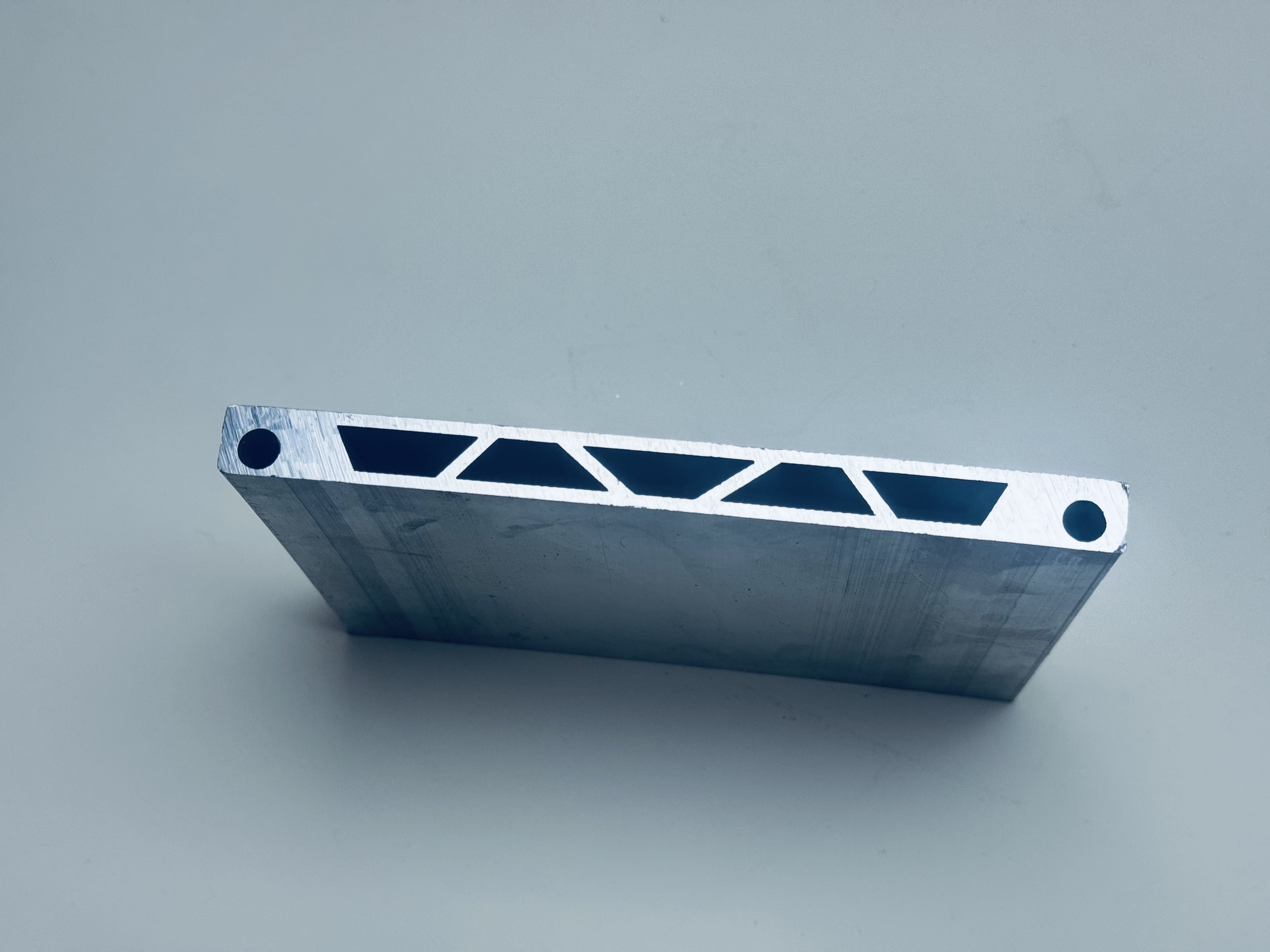

2020 Series – High-Strength for Aerospace & Defense

2024 Alloy – Aircraft Structural Components

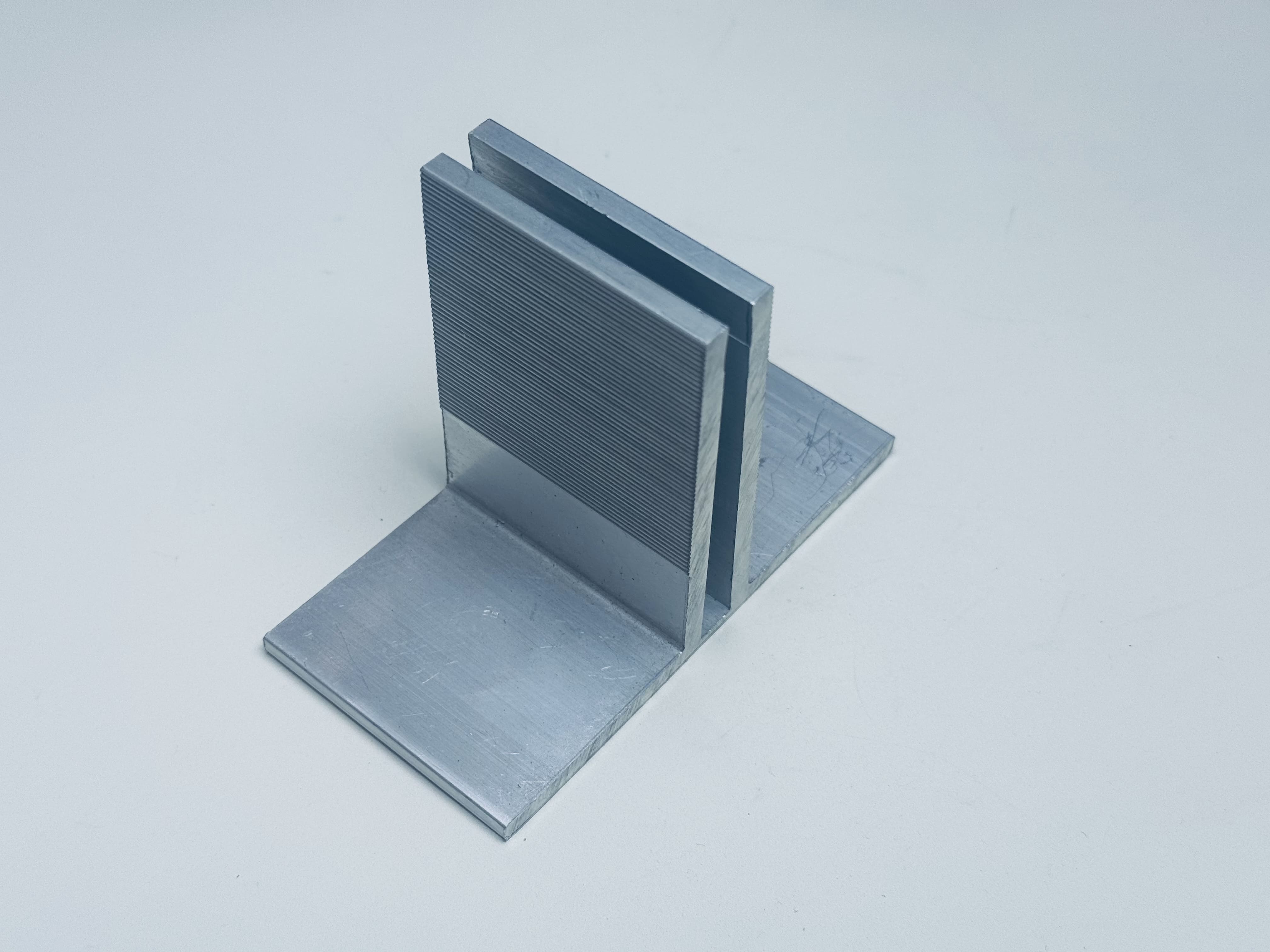

6061-T6 – Versatile & Corrosion-Resistant – Solar Panel Frames & Heat Sinks(Most Common)

7075 – Ultra-High Strength for Mechanical Parts

| Alloy | Main Elements (%) (Cu/Mg/Si/Zn/Other) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Density (g/cm³) | Extrudability | Heat Treatment | Primary Applications |

|---|---|---|---|---|---|---|---|---|

| 2020 | Cu:4.5-5.0, Mg:0.15-0.25, Li | 450-490 | 350-380 | 8-12 | 2.72 | ⚠️ Hard | T8 | Aerospace (lightweight) |

| 2024 | Cu:3.8-4.9, Mg:1.2-1.8 | 430-470 | 270-310 | 10-15 | 2.78 | ✅ Moderate | T3/T4 | Aircraft structures, rivets |

| 2040 | Cu:3.8-4.4, Mg:0.4-1.0 | 380-420 | 220-260 | 12-18 | 2.78 | ✅ Easy | T6 | Automotive/machinery parts |

| 2060 | Cu:3.5-4.9, Mg:0.5-1.2, Li | 480-520 | 380-420 | 8-10 | 2.72 | ⚠️ Hard | T8 | Advanced aerospace |

| 2080 | Cu:3.5-4.5, Mg:0.2-0.5, Li | 460-500 | 360-400 | 7-10 | 2.71 | ⚠️ Hard | T8 | Missile/spacecraft components |

| 3030 | Mg:0.6-1.2, Si:0.6-1.0 | 240-280 | 150-190 | 15-20 | 2.70 | ✅ Easy | T5/T6 | Architectural extrusions |

| 4040 | Si:0.8-1.2 | 200-240 | 120-160 | 18-22 | 2.70 | ✅ Easy | T5 | Heat sinks, electronics |

| 4080 | Si:1.0-1.5 | 220-260 | 140-180 | 16-20 | 2.71 | ✅ Easy | T5 | Electronic housings |

| 4545 | Si:0.8-1.2 | 230-270 | 150-190 | 17-21 | 2.70 | ✅ Easy | T5 | Thermal management |

| 5050 | Mg:1.1-1.8 | 180-220 | 100-150 | 20-25 | 2.69 | ✅ Easy | H32 | Marine/vehicle trims |

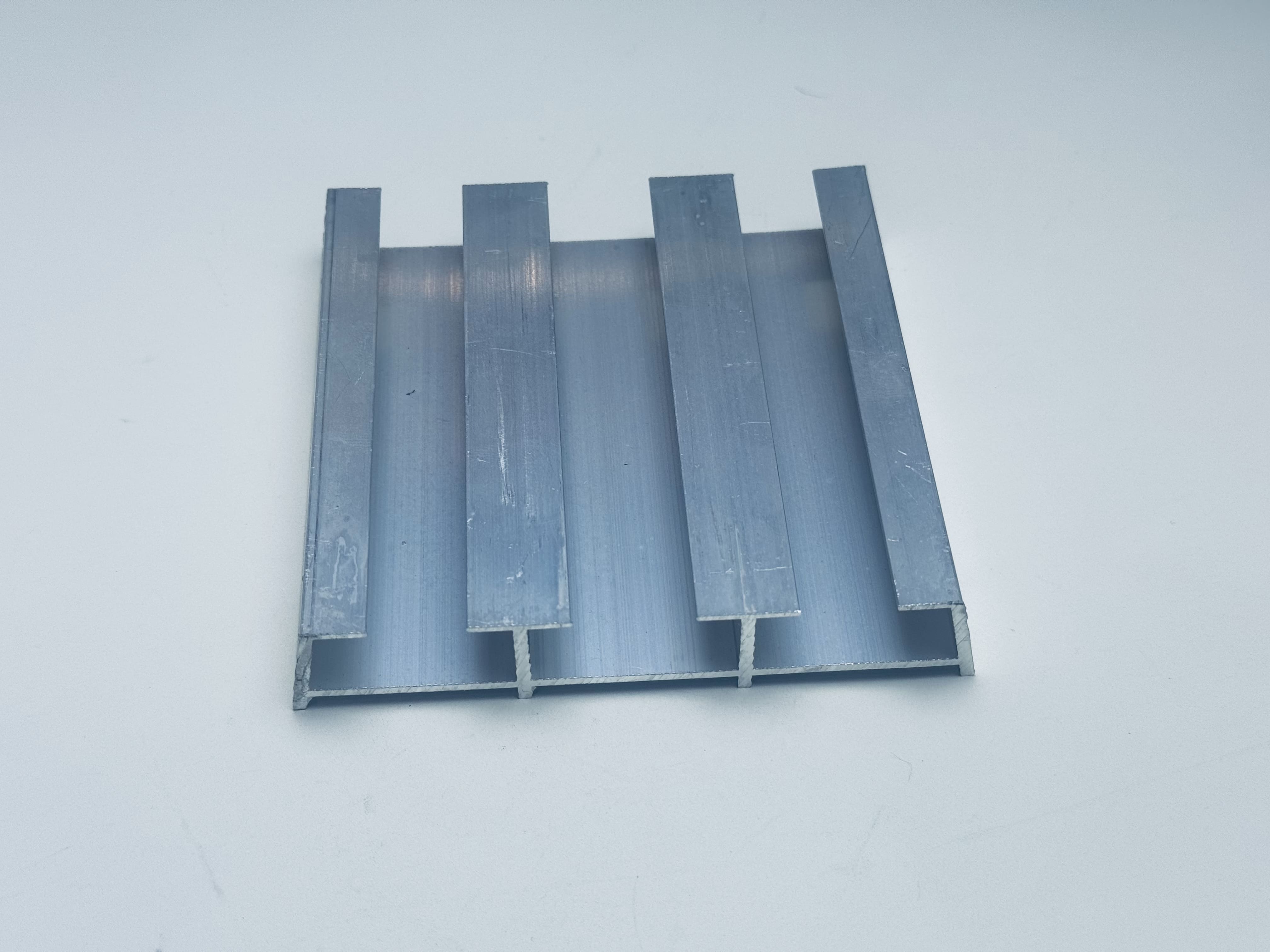

| 6000 | Mg:0.8-1.2, Si:0.4-0.8 | 260-320 | 180-240 | 12-15 | 2.70 | ✅ Easy | T6 | Industrial frameworks |

| 6061 | Mg:0.8-1.2, Si:0.4-0.8, Cu:0.15-0.4 | 290-310 | 240-270 | 10-15 | 2.70 | ✅ Easy | T6 | Universal structural parts |

| 7005 | Zn:4.0-5.0, Mg:1.0-1.8 | 350-400 | 280-330 | 8-12 | 2.78 | ⚠️ Moderate | T6 | Bicycle frames, transport |

| 7075 | Zn:5.1-6.1, Mg:2.1-2.9, Cu:1.2-2.0 | 510-570 | 430-480 | 5-10 | 2.81 | ⚠️ Hard | T6 | Military/aircraft (high-strength) |

| 8080 | Si:1.0-1.5 | 240-280 | 160-200 | 16-20 | 2.71 | ✅ Easy | T5 | Electronics (alternative to 4040) |

Key Highlights

Strongest Alloys: 7075 > 2060 > 2080 > 2020 > 7005 > 6061.

Lightest Alloys (Low Density): 2020/2060/2080 (~2.72 g/cm³).

Best for Extrusion: 6061/6000/5050 (easy to process).

Aerospace Focus: 2020/2060/7075 (high-strength, lightweight).

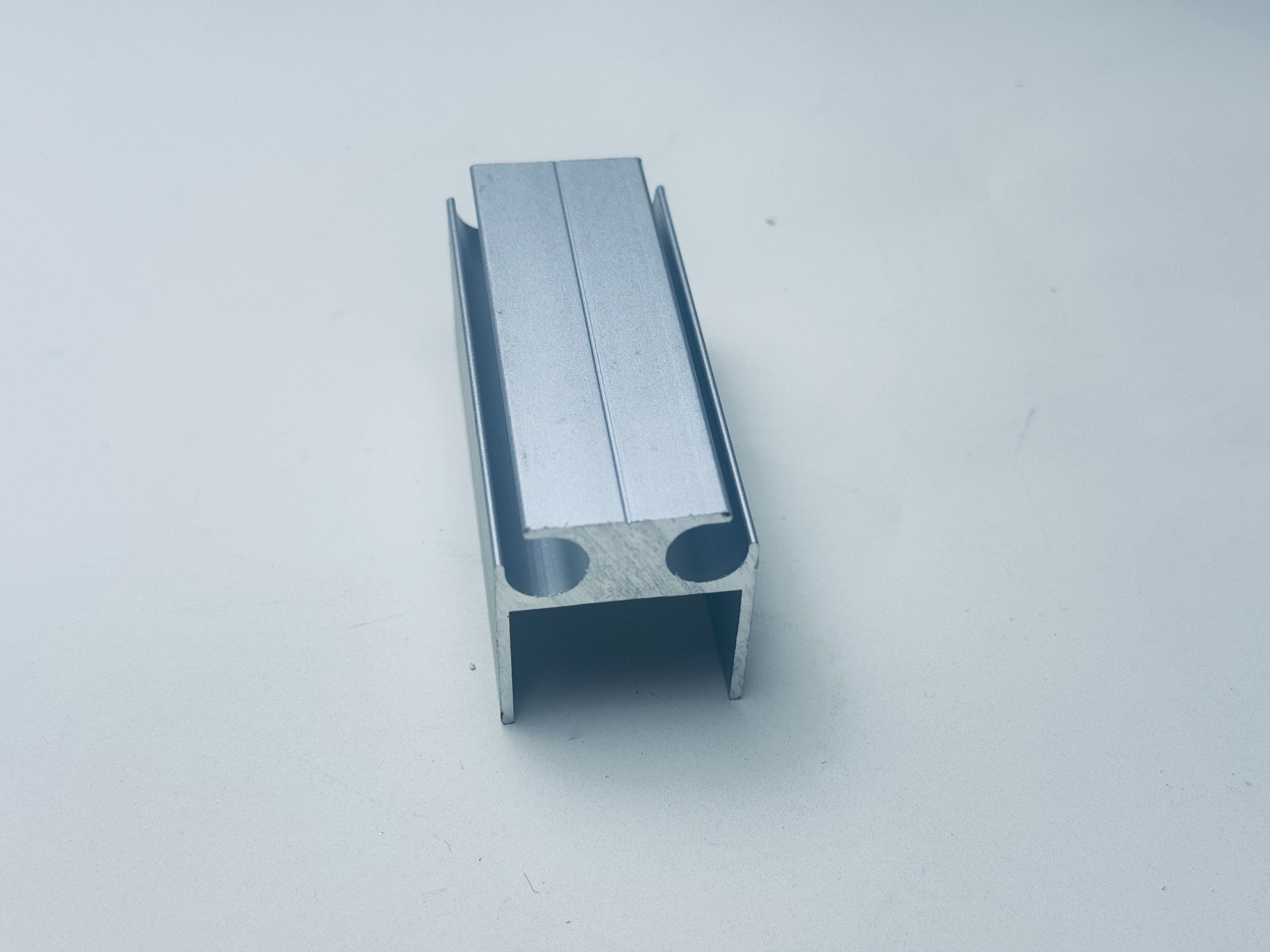

Thermal/Electronic Uses: 4040/4080/8080 (high silicon content).

Quick Selection Guide

| Requirement | Recommended Alloys | Avoid |

|---|---|---|

| Max Strength | 7075, 2060, 2080 | 5050, 4040 |

| Lightweight | 2020/2060/2080 | 7075 (dense) |

| Easy Extrusion | 6061, 6000, 5050 | 2020, 7075 |

| Cost-Effective | 6061, 6000, 3030 | Li-containing alloys |

| Heat Dissipation | 4040, 8080 | High-Cu alloys |